Revolutionising Aerospace Manufacturing: AML's Success with Productive Machines

By maximising the efficiency of machine tools, Productive

Machines empowers machinists to achieve superior quality parts

faster and with greater precision.

In an industry where efficiency and precision are paramount, our

innovative solutions mitigate chatter vibrations, lower tool

wear, and enhance surface finish.

We eliminate the iterations on machine tools - iterations that cause waste such as energy, time and materials - until manufacturers are satisfied with the productivity and quality. This is crucial not only for improving manufacturing quality but also for supporting global sustainability goals by reducing material and energy consumption.

The Client

AML is a leading player in the aerospace industry - globally

and in the UK, specialising in the precision machining of

complex metallic components.

As the aerospace sector increasingly focuses on lightweighting

and innovative technologies to support greener flying, AML has

continually advanced its machining capabilities to meet these

evolving demands.

With a strong commitment to delivering innovative manufacturing solutions, AML consistently positions itself at the forefront of the industry, addressing the challenges of complex geometries and advanced materials.

AML sought advanced technology to boost efficiency and reduce waste. This was crucial for building a business case to onshore key components for a major client committed to a net-zero objective.

AML sought advanced technology to boost efficiency and reduce

waste. This was crucial for building a business case to

onshore key components for a major client committed to a

net-zero objective.

Partnering with Productive Machines, AML achieved remarkable

results in optimising their machining processes.

The Challenge

There was a tier 1 aerospace supplier who were struggling with delivery from a previous incumbent on a business jet aircraft engine component, so they asked AML for help. They awarded them an initial contract to produce 3000 components with a view that if they were able to streamline processes - reducing cycle time and therefore reducing cost - they would be awarded a longer term contract.

Producing complex parts for a five-axis milling machine traditionally requires extensive engineering efforts.

AML needed a solution that could reduce cycle times, minimise tool wear, and enhance surface finish, while supporting their sustainability goals.

AML initially fully optimised the process using traditional engineering and reduced the cycle time to an hour, but this is where they became stuck. They approached Productive Machines for our expertise in Machining Dynamics and optimisation - wanting to use our Siemens NX plugin to optimise their tool paths.

The Solution: Harnessing High-Performance Computing

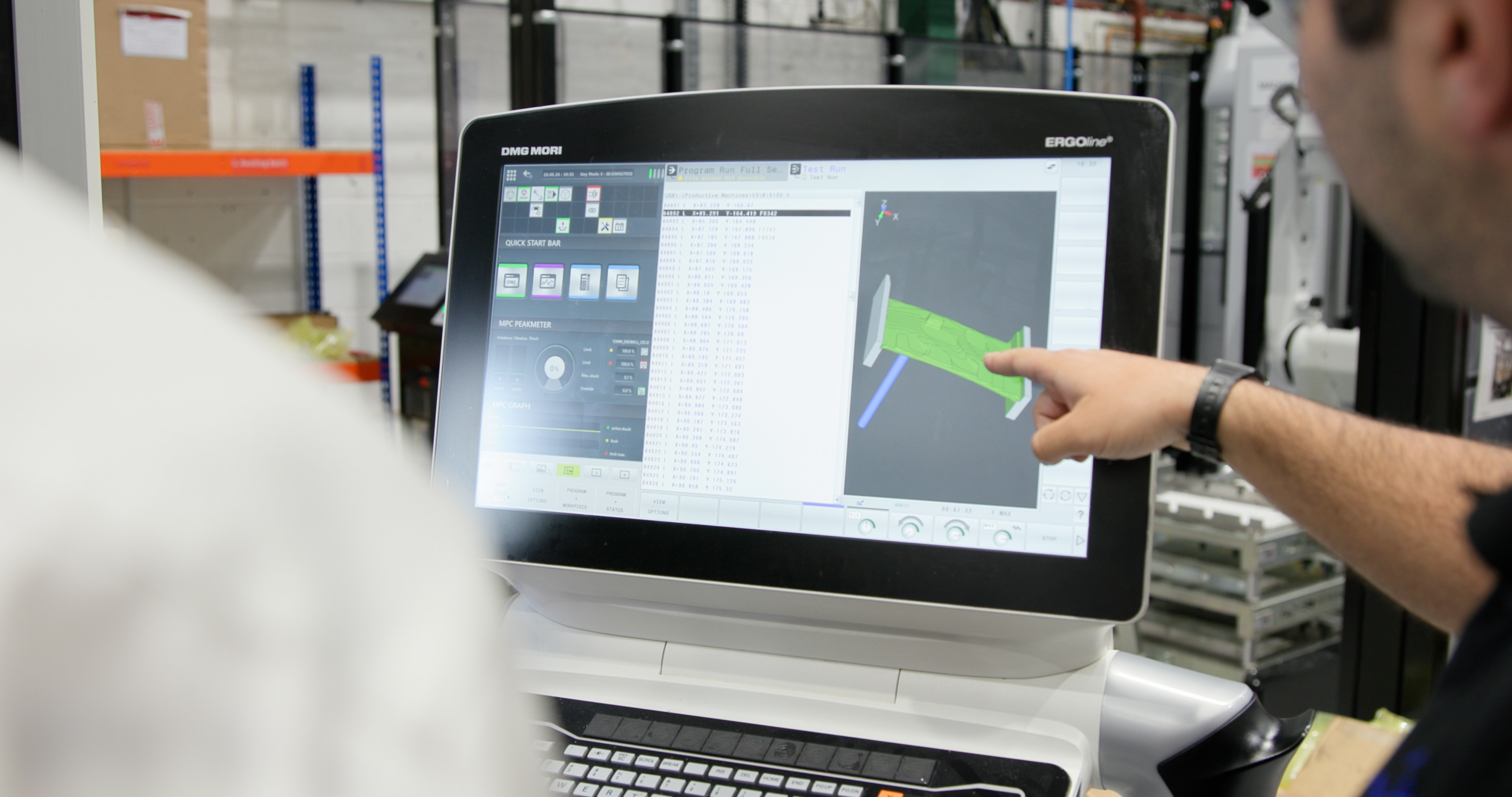

AML collaborated with Productive Machines, leveraging our autonomous toolpath optimisation technology. By integrating Siemens NX CAM with Productive Machines’ “Finesse” and a supercomputer, AML could simulate millions of combinations of machine parameters. This AI-based approach determined the optimal feeds and speeds for their toolpaths.

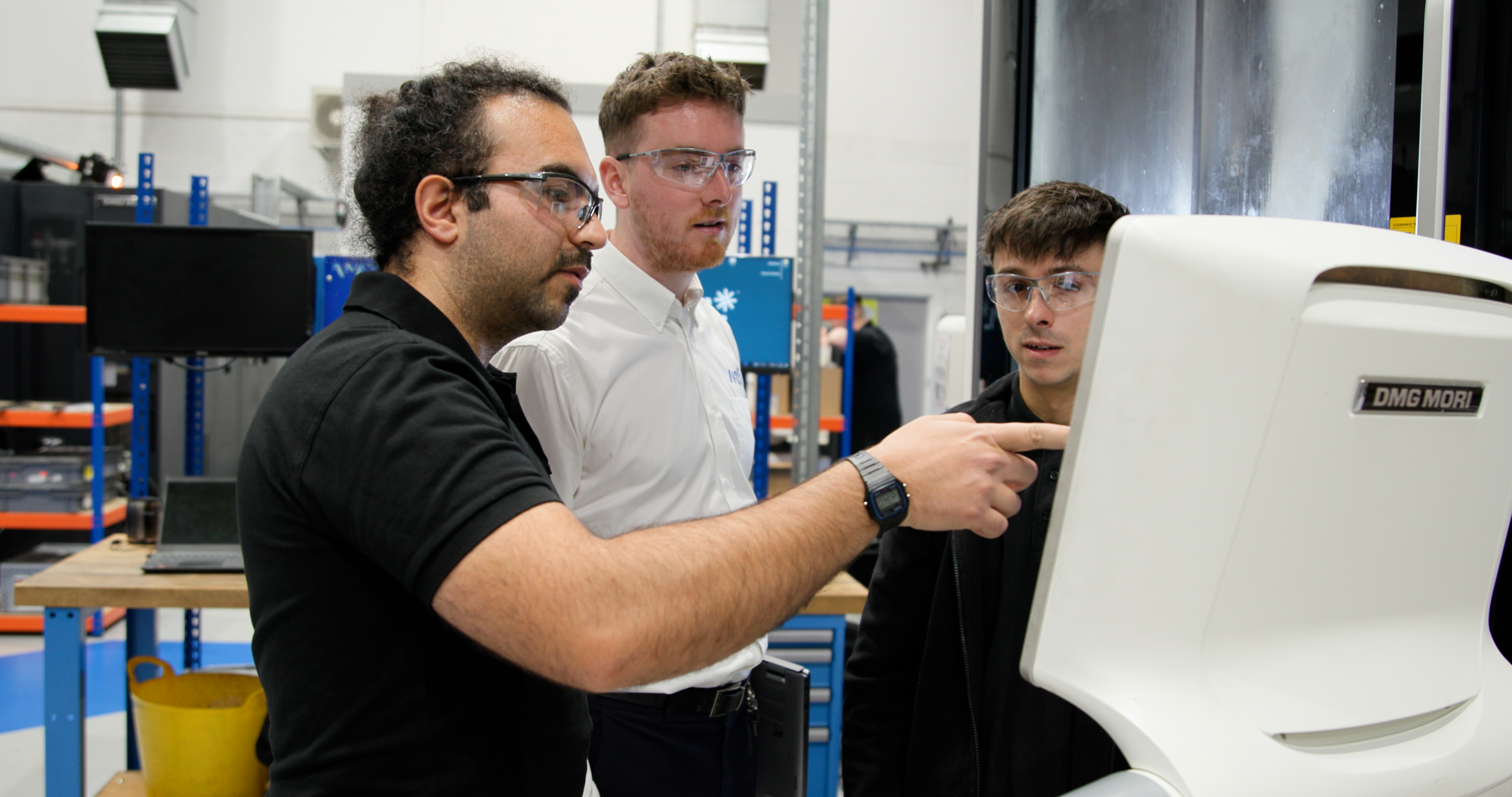

Implementation: Tap Testing for Precision

AML introduced a tap testing process, producing Frequency Response Function (FRF) data for eight cutting tools in a DMG Mori DMU 60 Eo milling machine. This data, organised within Productive Machines’ software, allowed for toolpath optimisation against chatter vibrations in Siemens NX CAM.

Results: Enhanced Efficiency and reduced costs

AML claimed 21% of reduced cycle times and significant gains in the lead times. Productive Machines’ cutting-edge algorithms ensured smooth operations free of chatter vibrations, systematically improving cycle time and surface finish. This not only accelerated production but also elevated AML’s quality standards, reinforcing their leadership in aerospace manufacturing.

Impact: Sustainable and Competitive Manufacturing

Through strategic collaboration with Productive Machines, AML optimised their manufacturing processes, contributing significantly to decarbonisation and sustainable manufacturing.

This initiative underscored the pivotal role of innovation and

partnership in driving operational excellence and maintaining a

competitive edge.

Dr. Gareth Morgan, Managing Director of AML who recently

received the King’s Awards 2024 for Enterprise Innovation

commented:

“Innovation is part of AML’s DNA, we are constantly looking at

innovative ways to improve our manufacturing processes and reduce

the carbon footprint. Productive Machines ticked all the boxes and

helped us become more competitive.”

Dr. Erdem Ozturk, who led the Machining Dynamics team at AMRC before starting Productive Machines (an AMRC spin-out), said: “Finesse is the result of more than a century's worth of cumulative experience in machining dynamics and software engineering, and yet, it is so easy to use. It runs in a familiar Siemens NX CAM environment and collates the data required for optimisation, making the lives of machine operators, application engineers, and CAM programmers much easier. Our autonomous optimization allows manufacturers like AML to shorten lead times, improve quality, productivity, and sustainability."

Keys to Success

- Leveraging supercomputing capabilities

- Utilising tap testing and machining dynamics

- Employing AI-based technology for precise toolpath optimisation

Productive Machines revolutionised AML’s machining process, achieving substantial improvements in efficiency, quality, and sustainability - highlighting the transformative impact of advanced technology in the aerospace industry and setting a new standard for manufacturing excellence.