Precision in Motion: A Collaborative Journey with AML towards Manufacturing Excellence

Challenge

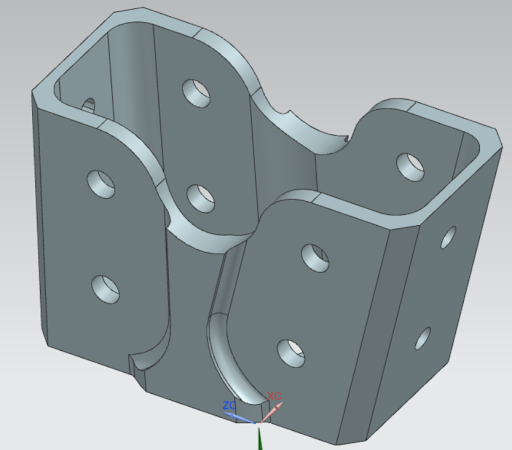

Productive Machines, renowned for its expertise in machining dynamics for milling processes, collaborated with AML, a leading 5-axis mill-turn manufacturing company based in Sheffield, UK. Specializing in Aerospace, Energy, and Defence sectors, AML had experienced rapid growth, doubling its turnover in just 12 months. To sustain this momentum, AML aimed to enhance overall cost-effectiveness and efficiency while leveraging Siemens NX CAM as their primary software platform. Recognising the potential for optimization, AML partnered with Productive Machines to streamline their manufacturing processes.

Approach

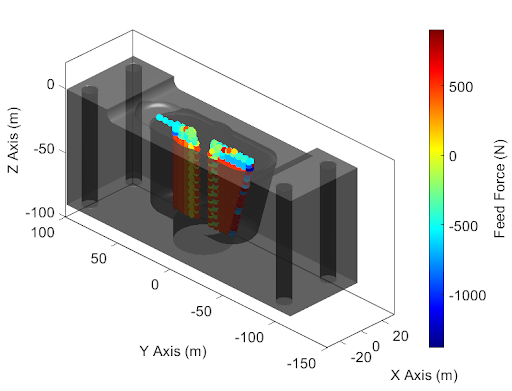

Productive Machines applied the feed rate scheduling solution across the tool path to control cutting forces in the process.

Methodology:

Siemens NX Integration: Leveraging AML's proficiency in Siemens NX, Productive Machines seamlessly integrated their optimization solutions into AML's existing workflow.

Systematic Optimization: Productive Machines developed a digital twin of AML's machining processes, allowing for virtual experimentation and analysis of feed rates across the toolpath.

Results

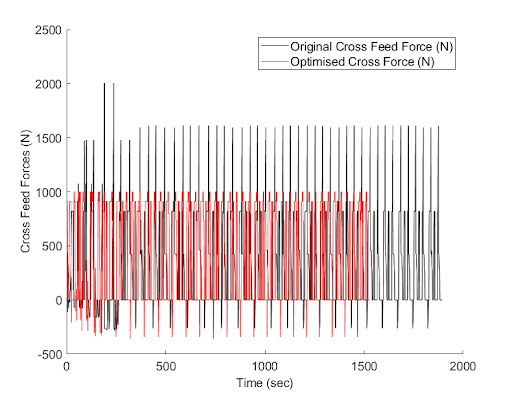

Through scheduling feed rates across the tool path, a remarkable 13% reduction in cycle time was achieved.Moreover, maximum cutting forces decreased from 2,000N to 1,000N, mitigating exceessive tool wear.

Conclusion

AML's journey with Siemens NX CAM and Productive Machines’ optimization demonstrates the transformative impact of digital innovation on manufacturing efficiency. By systematically optimizing machining parameters, AML achieved substantial improvements in cycle times and competitive advantage. This advantage is transferrable to other jobs to other parts in the portfolio.