Boosting Production Capacity Without Additional Machinery Investment

The Advanced Manufacturing Innovation Centre, AMIC, achieved significant efficiency gains by leveraging Productive Machines’ user-friendly optimization solution. This case study explores how the implementation of this technology resulted in over 20% savings in milling cycle time, translating to reduced costs and increased productivity in machining centres. This, in turn, enhances profitability without demanding additional capital investment in new machines.

AMIC Technology Centre

The Advanced Manufacturing Innovation Centre (AMIC) is a £100 million investment led by Queen's University Belfast, part of the Belfast Region City Deal. With a cutting-edge facility spanning 10,500 m² and a team of expert engineers, AMIC collaborates with industries to solve complex manufacturing challenges using advanced technologies. Their mission is to drive innovation in high-value manufacturing, creating competitive advantages, job opportunities, and attracting investment to Northern Ireland.

Challenges Addressed

AMIC frequently assists engineering shops, particularly in the aerospace sector, to enhance their machining processes. Long-term contracts often lead to entrenched machining methods. When faced with increased production demands, clients seek AMIC’s expertise to maximise their current machinery's efficiency, avoiding immediate capital expenditures on new equipment.

Challenges include:

- Improving throughput without new machinery.

- Achieving necessary tolerances in machining processes.

- Reducing cycle times

- Improving output quality

- Extending cutting tool lifespan

Optimization Process

Methodology

AMIC employed a comprehensive methodology to test the

effectiveness of Productive Machines' technology along with

solutions from Metrology Software Products Ltd (MSP):

Component Design: Using Siemens NX CAM software, a typical 3-axis aluminium component was designed, incorporating common milling strategies like mill contour, mill planar, adaptive contouring, and hole milling.

Probe Accuracy: Using Autoclock from MSP ensures all the probing measurements are accurate.

Part Alignment: Using MSP’s NC-PartLocator automatically aligns the part in the machine, so there is no need for manual intervention or complex fixturing.

Initial Machining: The part was machined using standard parameters provided by cutting tool manufacturers and an experienced machinist.

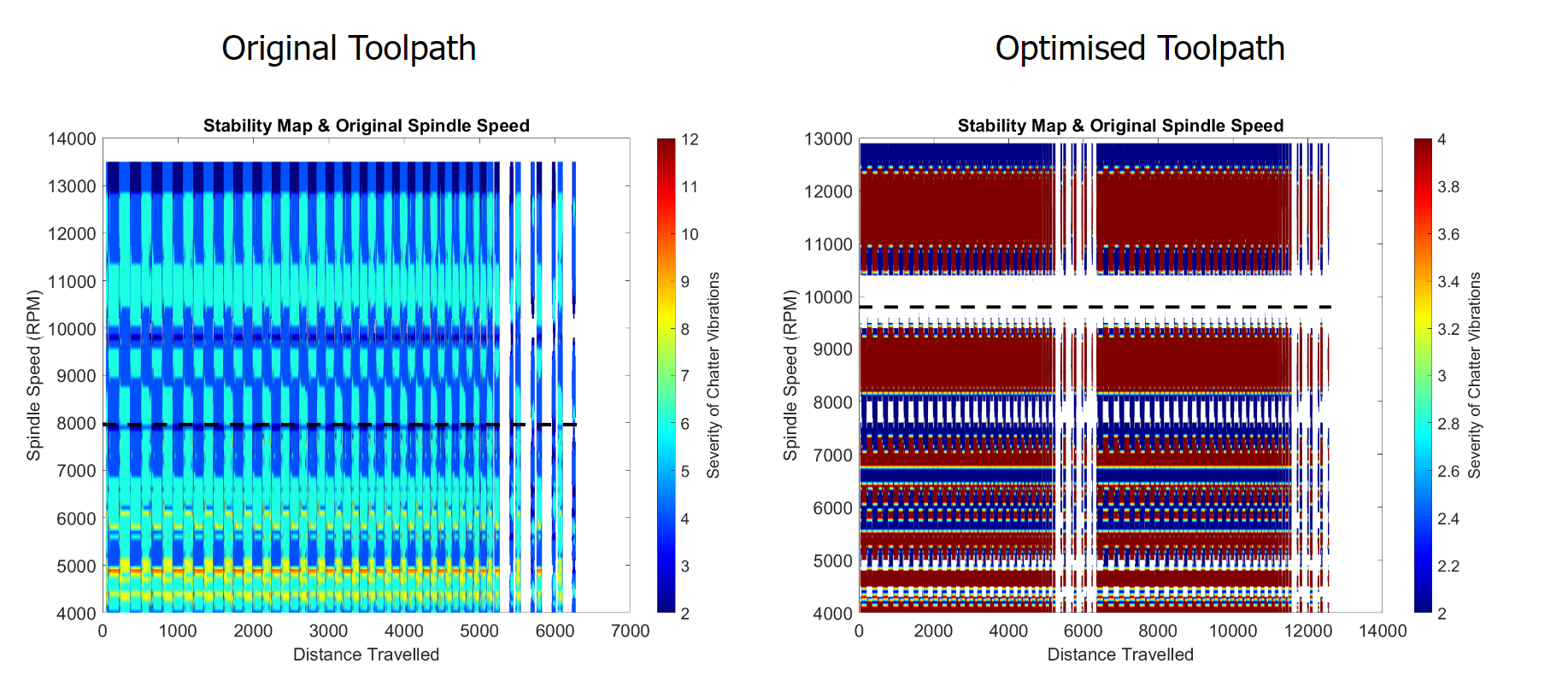

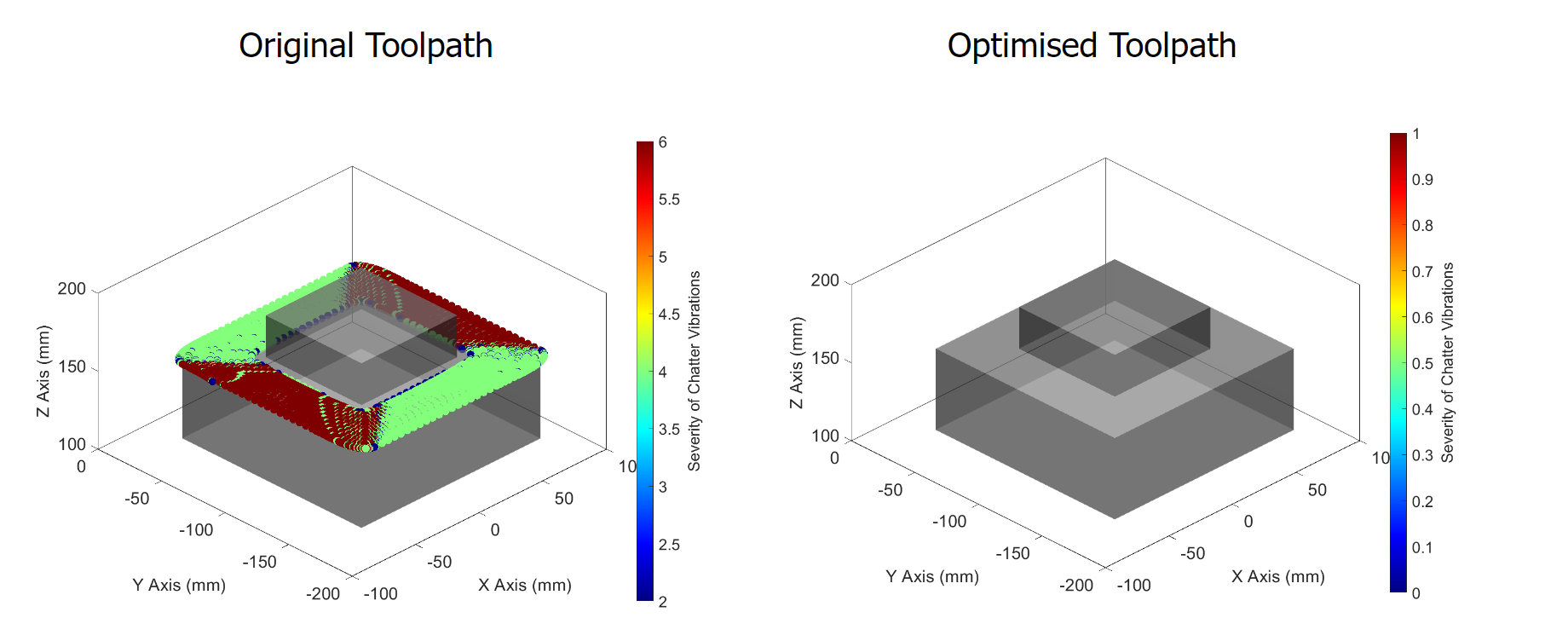

Optimization with SenseNC Finesse: AMIC utilised SenseNC Finesse, an autonomous optimization software plugin for CAM systems developed by Productive Machines. This solution obtains the best spindle speeds and feed rates against chatter vibrations.

Comparative Analysis: A second part was machined using the optimized toolpaths. Cycle time, surface roughness, and feature alignment were compared between the initial and optimized parts.

Results

The use of Productive Machines' Finesse plugin yielded remarkable improvements:

- Overall Cycle Time: reduced by 21%.

- Roughing Operation Cycle Time: reduced by up to 35%.

- Surface Finish: improved by 40%.

- Chatter Vibration: eliminated in both roughing and finishing operations.

- Part Alignment: achieved through MSP technology, eliminating feature mismatches when turning the part over.

Key Insights

- Cycle Time Reduction: the optimized machining process resulted in a 20% reduction in overall cycle time. The roughing operation cycle time saw a substantial decrease of up to 35%, while the finishing operation cycle time slightly increased to achieve a 50% improvement in surface finish.

- Quality Enhancement: the elimination of chatter vibrations in both roughing and finishing operations led to a significant enhancement in the surface quality of the machined part.

- Feature Alignment: MSP technology ensured precise alignment of component features, resolving issues with feature mismatches.

- Cost Savings and Efficiency: by reducing cycle times and improving surface quality without investing in new machinery, AMIC demonstrated how manufacturers could achieve significant cost savings and efficiency gains.

Conclusion

The AMIC Technology Centre’s collaboration with Productive Machines underscores the potential of advanced CAM optimization solutions to significantly enhance manufacturing efficiency. This case study illustrates a viable pathway for manufacturers to boost productivity and reduce costs without the need for additional capital investments in new machinery.

Testimonials

Alastair Cupples, CNC Engineer at AMIC, expressed his enthusiasm for the technology, stating, “This part originally had severe chatter. After optimizing with Productive Machines digital twin, we machined the part 21% faster with no chatter and a better surface finish. I am excited to be involved in this technology and optimising machining strategies via the Productive Machines toolpath optimizer.”

Glenn Rutherford, Head of Machining and Metrology at AMIC, highlighted the benefits: “Cycle times were cut by over 20%, and surface finish quality improved by over 40%. Obtaining the optimised machine parameters within the NX environment was easy, leading to top-quality parts. We can think of many clients who could benefit from this automatic optimization.”

This case study exemplifies how leveraging advanced optimization software can transform manufacturing processes, delivering substantial efficiency gains and quality improvements.