Increasing productivity and reducing noise for a machine tool OEM

Challenge

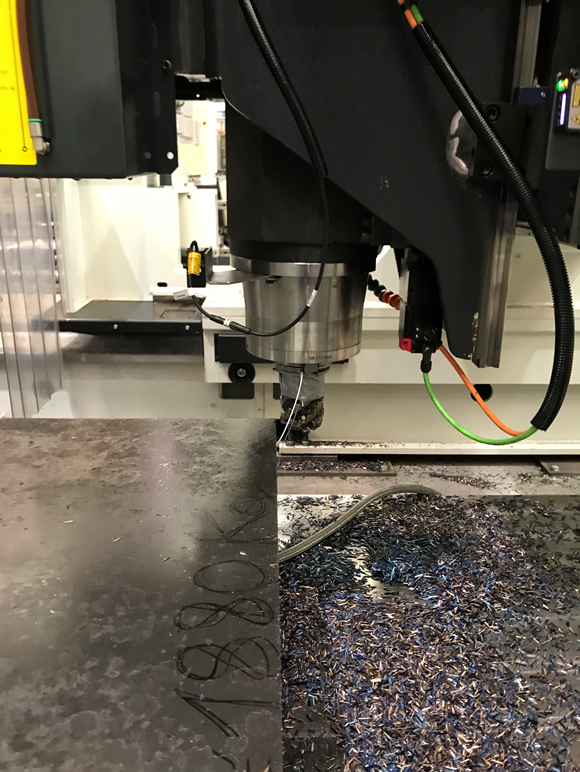

FICEP UK, a renowned supplier of structural steel and plate fabrication machine tools, observed excessive noise levels and disruptive chatter vibrations during the milling of slots on large structural steel pieces. These challenges threatened productivity and efficiency, prompting FICEP to seek solutions that could enhance material removal rates while mitigating noise, without compromising speed or quality.

FICEP turned to Productive Machines to seek an answer to their challenge. These challenges threatened productivity and efficiency, prompting FICEP to seek solutions that could enhance material removal rates while mitigating noise, without compromising speed or quality.

Approach

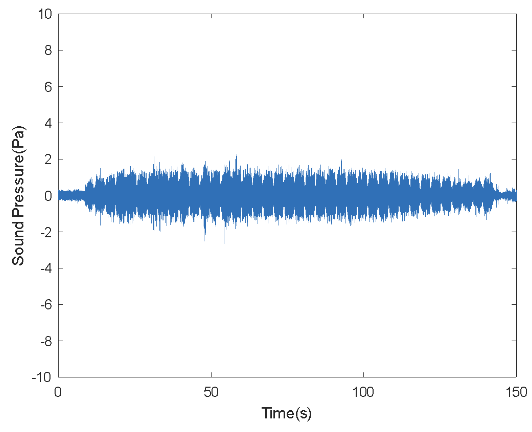

Productive Machines tackled the problem by optimizing machine settings using the TapStarter product. The solution did not need access to the Computer-Aided Manufacturing (CAM) file of the operation as the process was performed by a simple cut. The input required was the name of the workpiece material, the cutting tool parameters and a tap test of the installed machine tool assembly. The combination of these inputs enabled Productive Machines to suggest the optimum feeds and speeds in the process.

Results

Productivity Increase: FICEP experienced an impressive 110% increase in productivity, marking a significant advancement in their operational efficiency.

Cycle Time Efficiency: Through meticulous optimization, Productive Machines achieved a notable 53% reduction in cycle time, streamlining operations and enhancing overall productivity.

Noise Reduction: Productive Machines' interventions resulted in a remarkable fivefold reduction in noise levels, creating a quieter and more conducive working environment.

100% Productivity increase

50% Cycle time reduction

x5 Noise level reduction

Conclusion

Productive Machines identified the optimum spindle speed, depth of cut and feed rates to mitigate chatter vibrations while resecting the constraints of the machine tools such as torque and power capacity. A harmonious balance between productivity, cycle time and reduction in noise was achieved. FICEP UK's collaboration with Productive Machines exemplifies how targeted solutions can yield significant improvements in productivity, noise reduction, and cycle time efficiency.