We work closely with leading Computer Aided Manufacturing (CAM), Cutting Tools, Machine Tools & Machine Sensors Original Equipment Manufacturers (OEMs) to champion our technology.

Our Research Centres offer advanced manufacturing services to help you reduce cycle times, achieve right first-time-manufacture and avoid material scrap.

Taylor-made solutions for

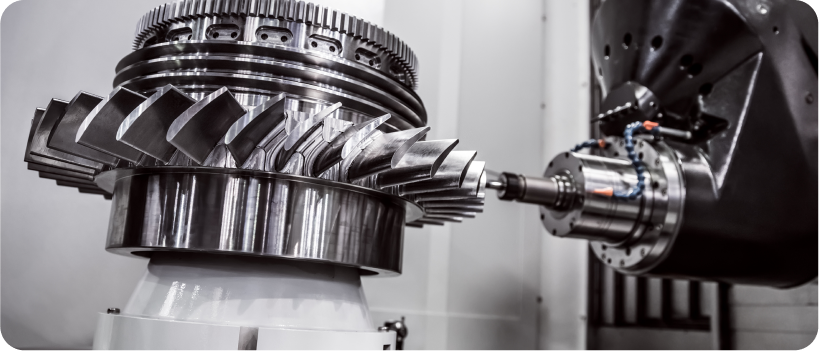

Increasing machine productivity

Mitigation of chatter vibrations

Achieving dimensional tolerance

Cutting force control

Precision surface finish

Chip thickness control

First time right approach

Tool breakage prevention

Eliminating waste

Planned Downtime

Saving energy and CO2 emissions

Chatter-free Manufacturing

We help mitigate chatter vibration problems by recommending the best feed rates and optimal spindle speeds.

Boost productivity and profitability

You can boost your productivity and profitability by reducing machine cycle time by up to 53%, eliminating material scrap, preventing cutting tool breakages, and reducing tool wear.

Right-first-time manufacture

Our optimization service delivers right-first-time manufacture: free your resources and make your machining operations more efficient and cost-effective.

Channel Partners

MSP uses metrology-quality data from touch probes to create intelligent manufacturing processes that result in right-first-time parts. MSP's fully automated solution has generated significant results for its customers, such as complex part setup reduced from 7 days to 4 hours, 157% increases in machine capacity, and 100% increases in productivity.

MachineWorks is the leading toolkit for CNC simulation and verification and is supplied embedded within a wide range of brands from major machine tools, CNC controller manufacturers and CAM software vendors.

Kistler is a global market leader in dynamic pressure, force, torque and acceleration measurement technology, with know-how in a multitude of industries and applications. Founded in 1959, the Kistler Group has grown hand-in-hand with its customers and employees.

CAM Integrations

We work closely with CAM companies to increase the accessibility of our technology from your own CAM software package.

NX is a powerful design-to-manufacturing integrated software solution that delivers innovative, high-quality products. NX software helps produce better products faster with next-generation design and manufacturing solutions using the digital twin.

Looking for advanced manufacturing services?

We partnered with Research Centres near you that help solve your challenges. They can offer tap testing and training services. We only work with providers that match our standards for quality and service.

The National Manufacturing Institute Scotland is accelerating productivity to grow our economy, develop a robust talent pipeline workforce, and help businesses create net zero manufacturing supply chains.

The Danish Advanced Manufacturing Centre delivers on-premise and project-based consultancy to solve problems related to metal cutting. Training to be shared with other companies or specifically designed is also on offer.

AMIC (part of Queen's University Belfast) is an industry-led, open access manufacturing and engineering innovation centre with state-of-the-art facilities and an expert engineering team, underpinned by academic excellence.

All of our trusted partners have a long track record in the CNC industry and are ISO certified.

Do you want to become a partner?

Offer customers a competitive advantage

Solve manufacturing problems

Develop new revenue generating services