Streamline Manufacturing

Increase productivity, reduce cycle times and save money with easy to use subscription app

Sustainable processes

Avoid wasted time, energy & material. First-time manufacture with fewer iterations

Quality Assurance

Eliminate errors and produce parts with optimal surface finish and dimensional accuracy

Preventative Maintenance

Monitor spindle health and prevent unplanned downtime

Empower engineers

Bring expert machining strategies to the shop floor

Equipment reliability

Carry out shop floor machine tool acceptance tests

Sustainable Machining

Waste

Reduction

Chatter elimination optimizes the cutting, reducing material waste and supporting sustainable manufacturing practices.

Resource

Efficiency

The longer cutting-tool life achieved through chatter reduction means less need for frequent replacements.

Energy

Conservation

Reduced vibrations lead to lower electricity consumption during machining.

Enhanced Product

Quality

Chatter elimination results in improved product precision, reducing defective parts.

Extended Equipment

Lifespan

Smoother machining operations reduce machine wear, prolonging the life of CNC equipment.

Safer Work

Environment

Reduced cutting noise improves workplace safety and contributes to a healthier workplace.

Products

Discover our products

Learn about Productive Machines SenseNC suite of machining

optimization

solutions that prevent chatter vibrations. These technologies help

manufacturers

reach the best part, faster, first time by applying optimal feed

rates and spindle speeds.

Products

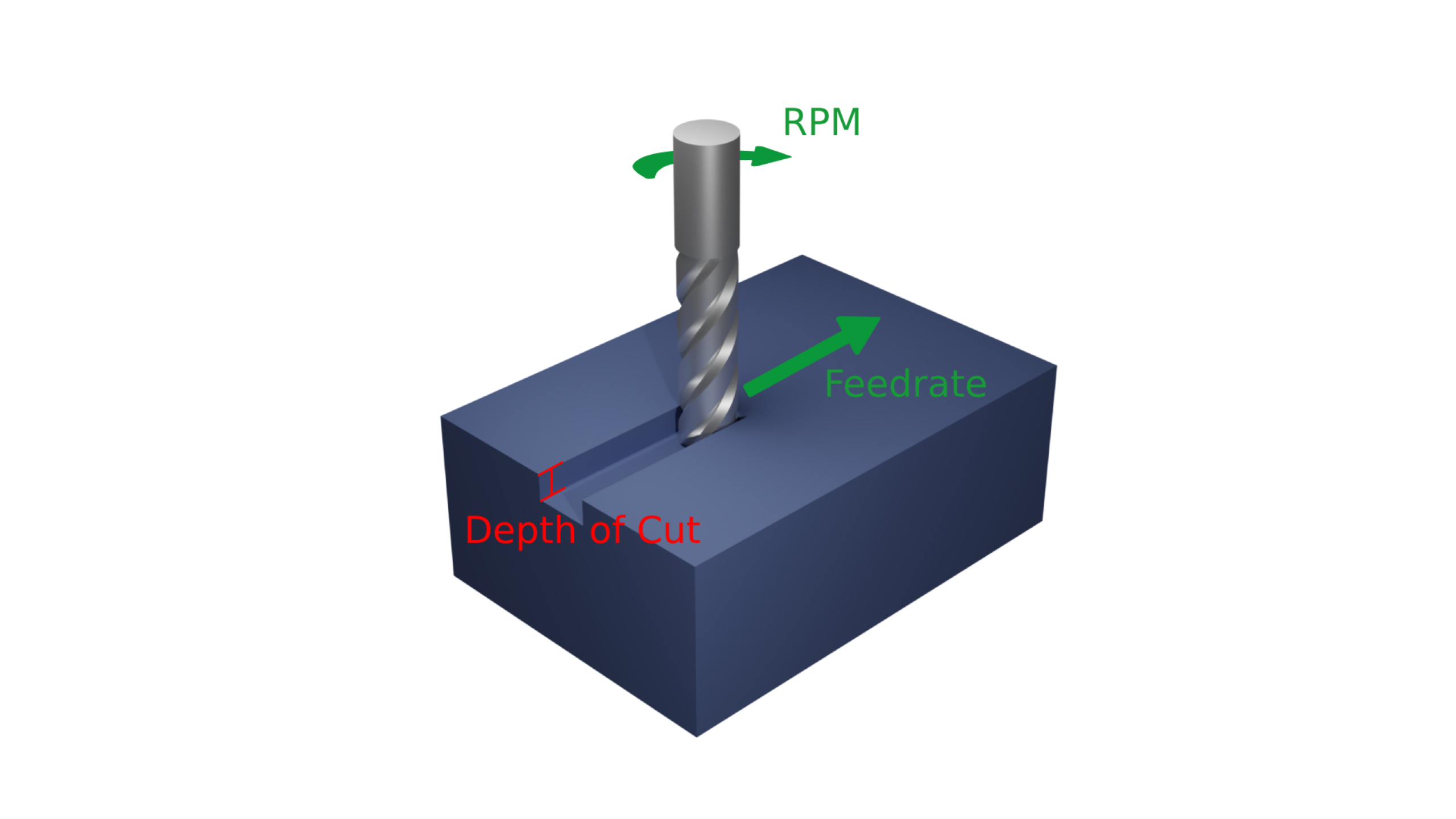

Feed Rate Optimizer

This web app offers instant optimized feed rates applied to straight milling operations with a flat end cutter. It can be used for process planning of untested milling operations to diagnose production issues by prediction of cutting forces the cutting tool experiences in the process. Its output can also be used while designing fixtures for the milling process.

Spindle Speed

Optimizer

The Spindle Speed Optimizer app helps

engineers to select the right set of

parameters for profiling providing

spindle

speed and depth of cut combinations

to

achieve stable milling processes.

Why use tap testing in combination with Productive Machines web apps?

To predict and identify the stability of machining operations against chatter vibration before cutting any metal

To assess the process transferability between the machine tools in the shop floor

To support the machine tool acceptance tests

Identify safe spindle speeds for machining by combining an

understanding of the behaviour of the installed cutting tool and

tap testing.

Plans and Pricing for our Apps

Try our Optimization to reach the best part, faster, right first

time

Start your 14-day free trial and see what's coming soon

TapStarter - Launch Bundle

Get one year free Essential Optimization and tap test training

when

you buy DigiTap standalone software and our tap test hardware kit.

£9,750

COMING SOON

Predictive Maintenance

Inspect the health of your spindle to

extend tool life and prevent downtime

(requires FRF data).

Feed Rate

Optimizer

Apply optimal feed rates to optimize the cutting forces of your machining process to increase speed.

£49/month billed annually

(when billed annually)

Essential Optimization

Apply optimal Feed Rates and Spindle Speeds to achieve the fastest chatter-free results (requires FRF data).

£149/month

(when billed annually)

Tap testing solutions

Gain insights into your machine's dynamics by collecting and analysing FRF data with our tap test hardware kit and DigiTap standalone software application.