Partners in Precision: How SaaS levels the playing field for small CNC machining businesses

In the world of manufacturing, precision is paramount. For small CNC (Computer Numerical Control) machining businesses,

achieving that precision can be the key to success.

However, it can feel like an uphill battle without the right tools and technology.

This is where Software as a Service (SaaS) applications come into play, offering a transformative solution to optimise machining processes,

eliminate chatter, and level the playing field for smaller firms.

This blog explains just what these applications can do for machining businesses like yours.

Understanding the Basics: CNC Machining and Chatter

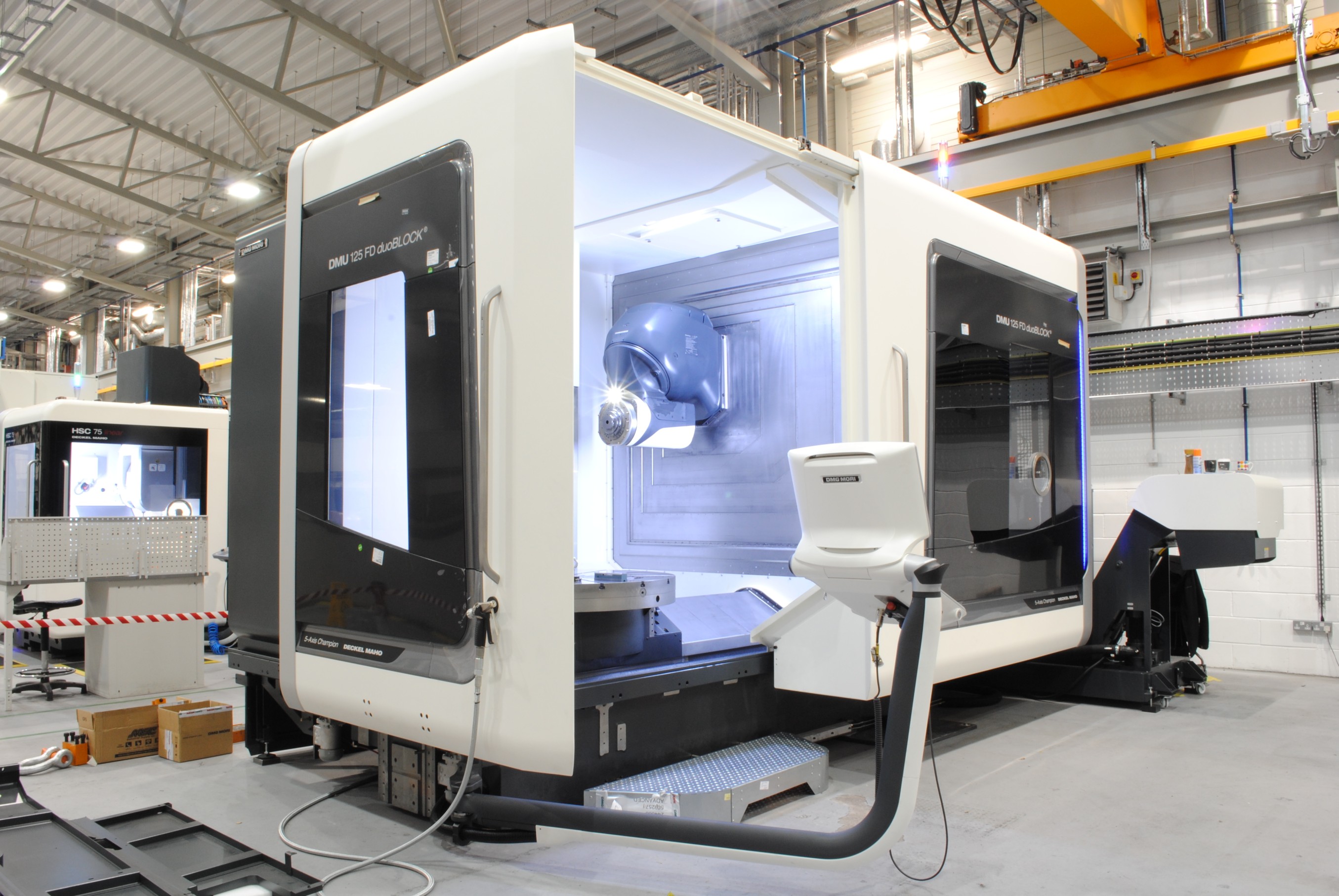

Before we delve into the transformation that SaaS applications bring, let’s establish some fundamentals. CNC machining is a manufacturing process that employs computer-controlled machines to shape and mould materials with remarkable precision. It’s the backbone of countless industries, from aerospace to medical device manufacturing.

Now, what’s “chatter”? In CNC machining, chatter refers to the undesirable vibrations or oscillations that occur when a cutting tool meets the workpiece. Imagine a shaky hand while writing with a pen; the result is often a messy, uneven line. In machining, chatter leads to subpar surface finishes, reduced tool life, and, most importantly, a deviation from the desired precision.

The Challenges Faced by Small CNC Machining Businesses

Productive Machines is on the leading edge of technology to optimise CNC machining. An artificial Intelligence (AI) startup from Sheffield in the UK, transforming how manufacturers manage milling machines.

Previously, the tech-based solutions to these precision issues involved expensive software and hardware, which needed lengthy and complex implementation processes. This meant they were beyond the reach of smaller machining firms.

Only giant manufacturers in sectors like aerospace could afford to implement these kinds of solutions. For most other manufacturers, the path to genuinely efficient working was blocked by cost issues.

Competition with Larger Firms: David v Goliath

In the world of manufacturing, size often translates into an advantage. Larger firms have the resources to invest in cutting-edge technology and maintain extensive R&D departments. For small CNC machining businesses, this could mean being left behind in an increasingly tech-driven industry.

This is where SaaS applications for precision manufacturing enter the scene as a great equaliser.

Benefits of SaaS for CNC Machining: Levelling the Playing Field

The growth of SaaS applications in CNC programming offers a multitude of benefits that are especially advantageous for smaller CNC machining businesses:

- Cost-Effectiveness: Implementing SaaS solutions comes at a fraction of the cost of developing custom in-house software. This means that even businesses with limited budgets can access powerful tools. They are available on a much more affordable subscription basis.

- Accessibility: SaaS applications are typically cloud-based, allowing remote access and collaboration. This means that regardless of location, teams can work together seamlessly. They are also far more accessible because, to enjoy its benefits, a SaaS app does not require in-house PhD-level expertise to implement and maintain.

- Ease of Implementation: SaaS solutions are designed to be user-friendly and easy to integrate into existing workflows. This minimises downtime and accelerates the adoption process.

With the barriers to more efficient working removed, smaller CNC manufacturers can win big:

- Less wasted material: Chatter-damaged workpieces can’t be used, which means waste. This waste material is expensive to buy and energy-intensive to produce.

- Longer tool life: Chatter makes tools wear out faster, which costs more money and creates more waste. Replacing tools has a double financial impact, leading to waste and expensive downtime.

- Lower energy use: Machinists spend much time experimenting to find the right drill speed that stops chatter. All of this experimentation wastes energy and money.

Now, let’s dive into the heart of the matter: how SaaS applications transform CNC machining, particularly in chatter.

Eliminating Chatter: Precision at Its Finest

Imagine a professional chef wielding a knife with utmost precision, smoothly slicing through their ingredients. There’s no hesitation, no deviation from the intended path. There is no trial-and-error to work out the best ways of cutting before the real work can begin. This precision is what SaaS applications can bring to CNC machining.

Chatter is the nemesis of precision in machining. It’s the unpredictable shaking that results in jagged edges and flawed products. The usual way to deal with it has been trial and error – trying out different machine settings until the vibrations causing the chatter are minimised. These ways are not helping businesses, and they are not helping the planet.

By contrast, SaaS applications for precision machining come armed with predictive algorithms. They use a digital twin of the machining process to work out the likely chatter effects and provide machine settings to eliminate it. It’s like having an expert chef’s steady hand guiding the cutting tool.

Different types of apps

Apps for optimising machining are now starting to hit the market. For instance, at Productive Machines, we’ve just launched our Feed Rate Optimizer web app – the first in a range of intelligent tools being developed by the team. It empowers manufacturers to make fast decisions about using untested milling processes and to get accurate forecasts of the forces expected on the cutting tool, thus unlocking significant cost and time savings.

This smart cloud-based application enhances machining strategies in the $153.8 billion CNC machine tool market.

The team has been developing tools that will make precision machining more efficient and more accessible to manufacturers of all sizes. A suite of cloud-based optimisation and predictive maintenance products will be released in October 2023.

Real-World Examples: CNC Businesses Thrive

To underscore the transformative impact of SaaS, let’s turn to real-world success stories. In Productive Machines’ work with global manufacturers such as Renault and MASA Aerospace, our technology has shown it can:

- Cut machining design and set-up time by 20%

- Cut cycle times by up to 53%

- Cut operational and maintenance costs by 25%

- Reduce cutting tools costs by 11%

- Deliver a five-fold reduction in cutting noise.

So, the technology offers a huge productivity increase, massive cost reductions, and a significant sustainability impact.

These success stories demonstrate that SaaS applications aren’t just a technological advantage but a potential business transformer for small CNC machining businesses.

Decades of expertise in each SaaS tool

These apps may be simple to use, but that ease hides the years of experience and research that have gone into democratising precision cutting.

It was 2021 when Dr Erdem Ozturk spun Productive Machines out from the University of Sheffield Advanced Manufacturing Research Centre (AMRC), but the journey began long before that.

During his studies, Erdem researched a fundamental problem blocking the path to genuinely efficient CNC machining. The chatter issue has been a severe frustration in machining for many decades.

In 2010, Erdem began working with AMRC, seizing the chance to bring his theories to life for the high-tech industries housed at the advanced manufacturing park. The AMRC’s world-class manufacturing infrastructure and a steady stream of advanced machining challenges set the stage for success.

At the AMRC, new ideas are applied to some of the world’s most demanding manufacturing challenges. Startups learn from experts, tackle new problems, use the latest tools, and collaborate with big companies to bring their ideas to life.

The AMRC isn’t just about ideas – it’s about making fundamental changes. It’s all about taking the best ideas and turning them into real things that make a difference for everyone. That is Productive Machines’ vision too.

Erdem led a research team that pushed the boundaries of machining dynamics using bespoke digital twins to eliminate chatter. By digitally modelling the process and optimising the machine settings using machine learning, Productive Machines can reach a chatter-free solution in minutes, a solution that trial and error could not achieve in years.

This opens up the reality of chatter-free machining. It improves productivity by up to 50%. It prolongs tool life. It saves expensive staff time. And now, it is available to all as a suite of affordable apps.

The team grew from one to 20, encompassing staff, PhD students, MSc students, and visiting researchers. Over a decade, Erdem honed its capabilities and generated revenue through AMRC partnerships. This fusion of leadership, business acumen, and research laid the foundation for Productive Machines.

Today, our impact spans several industries, from medical to construction. With £3 million in investment behind us and a staff of 19, we’re on a growth trajectory, still benefiting from AMRC’s partnership, and charting an ambitious course for 2023 and beyond.

Democratising leading-edge expertise with SaaS apps

The transformative impact of accessible SaaS applications on small CNC machining businesses cannot be overstated. They level the playing field, enhance precision, and propel these businesses into a future where size no longer defines success.

From small tool shops to global manufacturing giants, SaaS applications make transformative results accessible to all.