Productive MAchines & KISTLER Announce New Partnership

Productive Machines is now announcing a partnership with the Kistler Group covering our extended services to optimise machining processes, with a particular focus on milling applications.

Kistler is the global leader in providing modular solutions in dynamic measurement technology for pressure, force, torque and acceleration.

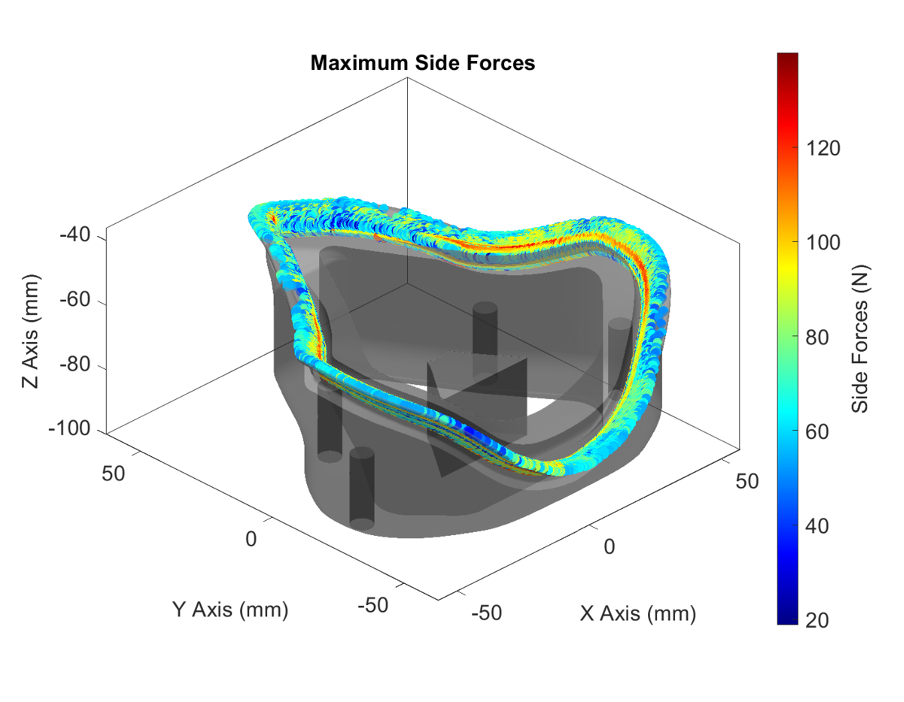

The collaboration between Kistler and Productive Machines offers Kistler customers a range of value-added services in machine tool analysis: methods such as dynamic stiffness mapping, cutting force simulations and feed rate scheduling will help to minimise milling force spikes and maximise tool life and performance. Chatter vibrations can also be minimised via adaptation of spindle speed based on stability maps. Another focus of the partnership is holistic optimisation of CAM files as an aid to improving productivity and quality.

WORKING TOGETHER TO PROVIDE THE BEST EVER INSIGHTS TO THE MACHINING PROCESS

For optimisation of process optimisation considering chatter vibrations, the physical stage of our service is performed with a tap-test using an impulse hammer. Resulting vibrations are measured with IEPE accelerometers, and a modal analysis then determines the dynamic behaviour of the milling machine.

Through Kistler, we are now offering DIGI-FORCE – a new digital service to determine key parameters of a machine setup. Various levels of the DIGI-FORCE service are available, and it can be combined with physical measurements to obtain a complete account of machine and tool capability and performance. The DIGI-FORCE OPT service adds the FRF file data from the machine measurement to the optimised CNC program – so chatter vibrations, tool wear and machine breakdowns can be significantly decreased or even eliminated.

Researchers and production engineers who opt for these services benefit from simulated force levels as the basis for optimising their CNC machining programs – leading not only to enhanced productivity but also reduced effort for R&D and process development.

More information is available on the Kistler website: Click here