Tap Testing 2.0: Why ‘hammer time’ remains best practice for machine tool manufacturers

The tap test is one of the oldest tools in the box for assessing the quality and integrity of machines, materials, components and structures. It relies on simple physics: the kinetic impulse of a hammer strike dissipated as vibration and sound. But behind that simplicity, there is abundant opportunity to make manufacturing better and more intelligent.

The origins of the tried and trusted technique of tap testing can be traced back to the age of steam, when ‘wheeltappers’ checked the integrity of train wheels by listening to the sound they made when struck with a hammer.

Wheels in good condition sound different to those that are damaged.

Cracked wheels simply don’t “ring true”.

Checking the integrity of train wheels remains vital, lifesaving work. Fatigue cracks in steel wheels occur through routine use and remain one of the main reasons for misalignment in railway trucks and, therefore, train derailments.

While wheeltapping has given way to newer techniques for checking truck wheels in most parts of the world, the act of striking an object with a small instrument, typically a specialised hammer or a tapping device, and analysing the resulting vibrations or sounds produced remains the most widely used nondestructive testing method for manufacturers.

Tap testing continues to be used frequently, both by high-volume manufacturers and in high-value production environments such as medical, aerospace and defence, due to its simplicity, portability and low cost. One tool can cover every machine on the factory floor.

The versatility of tap testing means that it is used for a variety of purposes, including:

- Quality Control: Manufacturers use tap testing to assess product quality during or after production quickly. It helps identify defects or inconsistencies in materials or components

- Material Characterisation:It is used to determine the mechanical properties of materials, such as stiffness, elasticity, and damping characteristics.

- Composite Materials Testing: Tap testing is particularly useful for composite materials, where delamination or voids can be challenging to detect using other methods.

- Bonding Quality: It can be used to assess the quality of adhesive bonds, such as in the automotive industry for evaluating the bonding of various parts.

- Research and Development: Tap testing is also employed in research and development to study the acoustic properties of materials and gain insights into their behaviour.

The fact that hitting things with a hammer and listening to the sound they make has survived as a technique and even thrived into the era of smart factories is because tap testing has evolved to the extent that this inexpensive, easy-to-use technique is now truly intelligent.

Tap Testing 2.0: The digital future of tap testing

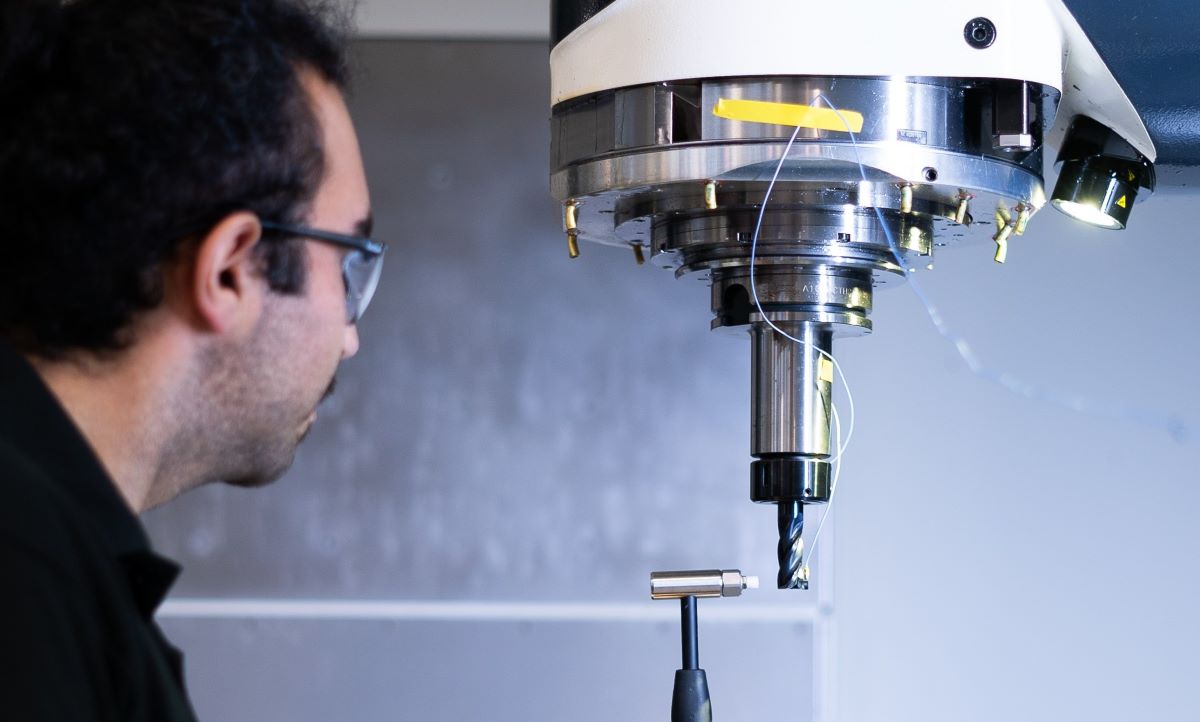

When performing a tap test, an operator uses a controlled and consistent force to tap the surface of the material or component with a digital tap hammer. The tap can be gentle or hard, depending on the application and the material tested.

Where traditional tap testing relied on skilled individuals to interpret the sounds made by the struck object, such as a machine tool, today’s digital tap tests are much more sophisticated and precise.

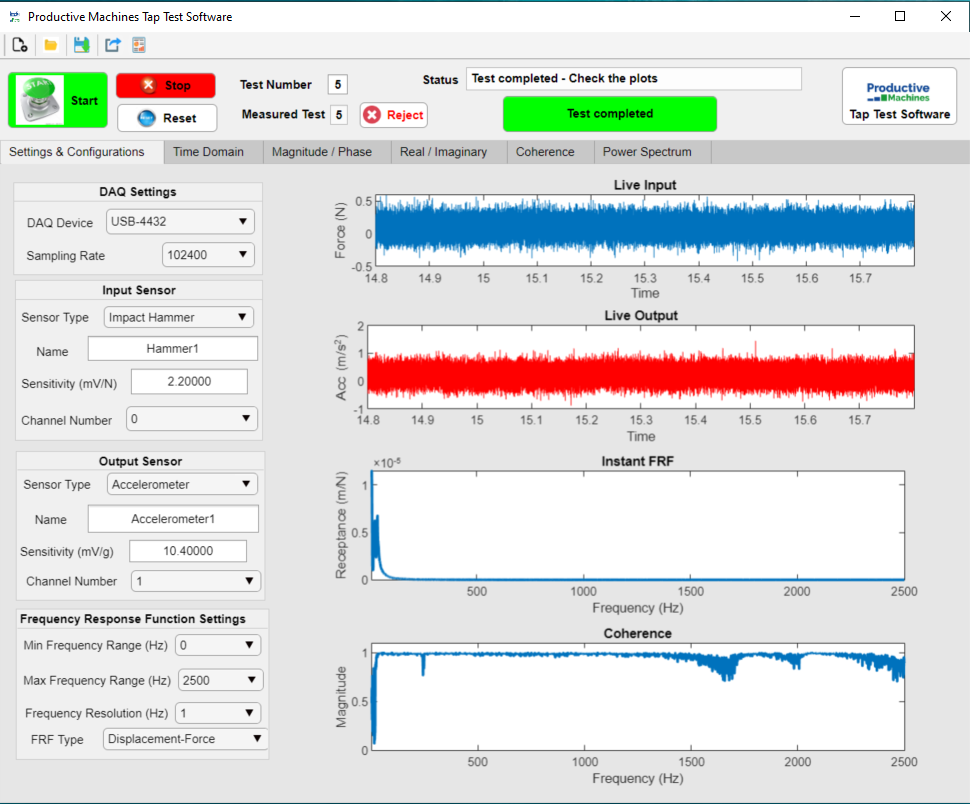

Instead of transmitting vibration responses to the ear as an acoustic sound wave, a digital tap hammer sends the vibration response as data to a computer for recording and analysis.

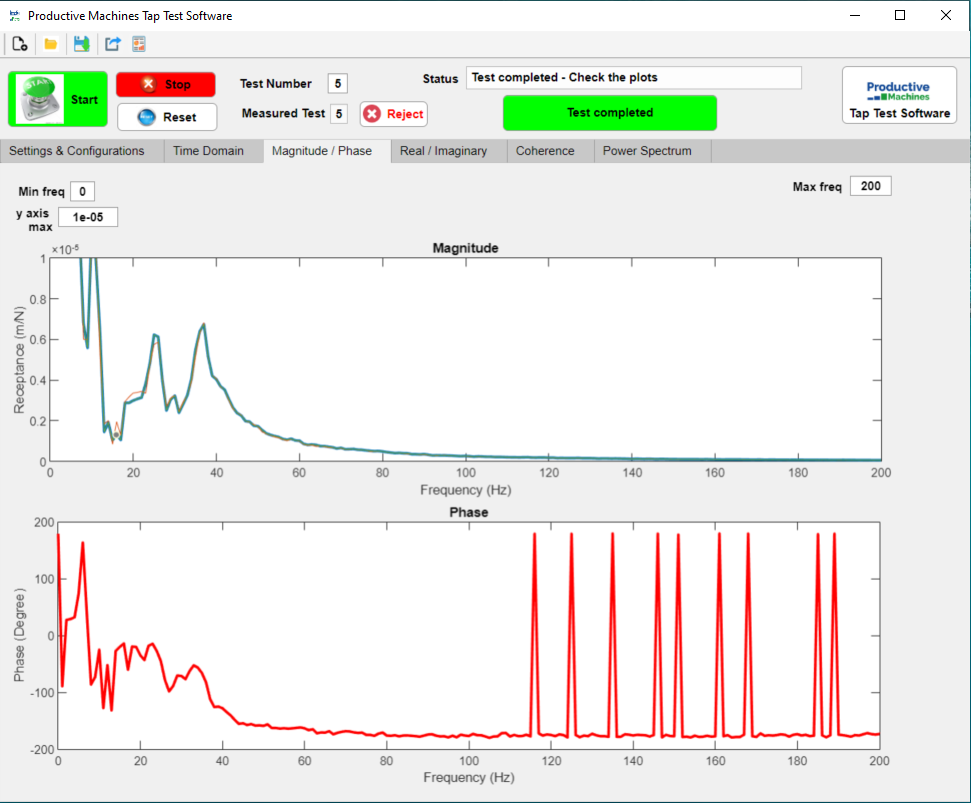

Specialist software then calculates the precise frequency response from those vibrations, considering parameters like the frequency, amplitude, and decay rate of the vibrations, and enables an exact analysis of that tool's unique characteristics and condition.

The data is compared to known standards or reference values to determine quality and integrity of materials, components and tools. Anomalies or deviations from the expected response can indicate defects, such as cracks, voids, delaminations, or structural weaknesses.

The ability to interpret that data consistently, accurately and more deeply has been greatly enhanced over the last decade by a new generation of analytical tools and Artificial Intelligence (AI) functionality that can identify emerging issues earlier than even the best experts, create digital twins of manufacturing machines, and model optimal working parameters.

Precise acoustic analysis from a digital tap hammer

At a point when many manufacturers are transforming digitally and seeking to make greater use of data and tools such as AI, the digital tap test has become a powerful and portable tool – one that can be moved from machine to machine to help optimize performance and power condition monitoring and predictive maintenance activities.

Our interest in tap testing comes in two forms: optimizing machine tool operations and making condition monitoring accessible to all manufacturers. Both rely on digital tap tests.

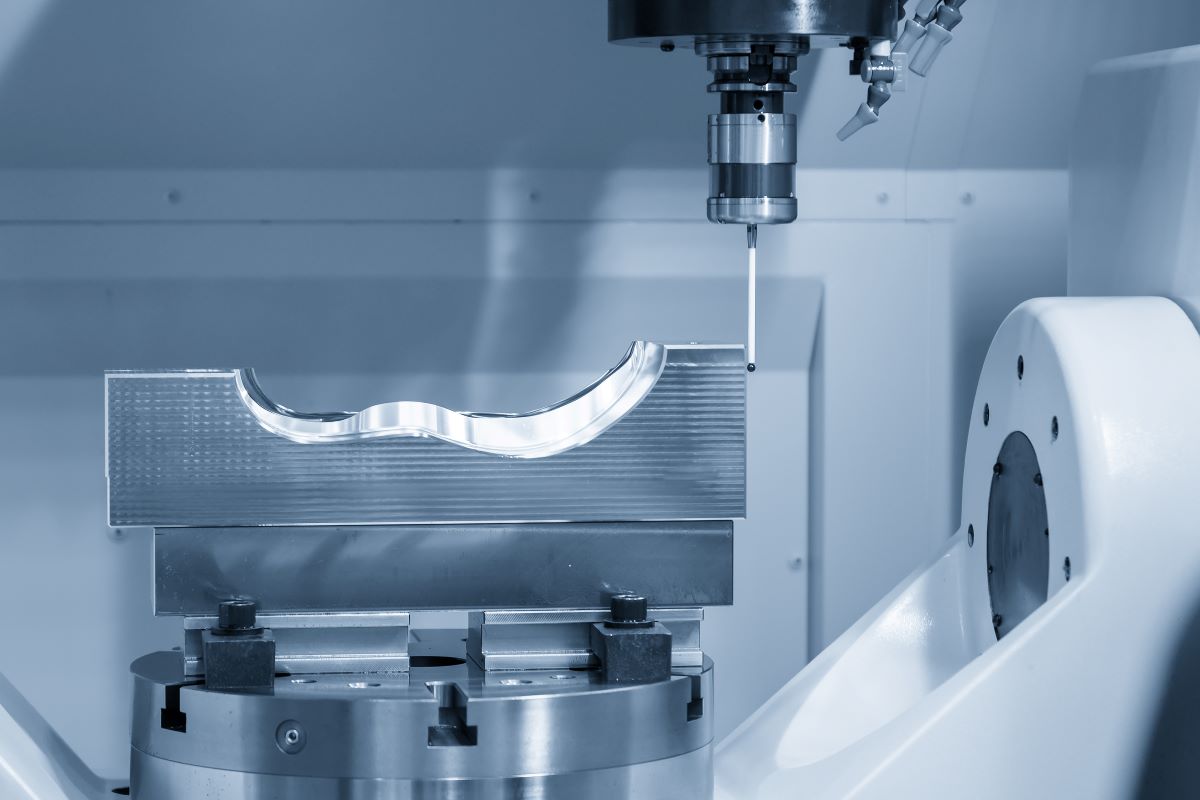

We help manufacturers understand machining dynamics, including how cutting forces affect machine tool performance, to eliminate the chatter vibrations from milling processes that result in an irregular, poor-quality surface finish.

A machine operator armed with a digital tap hammer and access to our AI-enabled software can quickly tap their machine tools to obtain a vibration response that shows precisely how that machine will perform once cutting forces are applied.

By considering the unique characteristics of each machine tool, which we can only achieve through a digital tap test, we generate a stability map revealing the precise combinations of spindle speed and feed rate that minimise or eliminate chatter and, therefore, maximise productivity and part quality at each stage in the milling or cutting process.

Stable cutting conditions deliver a more regular surface finish, resulting in fewer failed jobs, wasted parts and materials. But the productivity benefits go further: machine tool users know precisely where and when they can cut further and faster, enabling them to boost throughout and produce more high-quality parts with the time and assets available.

Using data from the digital tap test and AI to interrogate the results eliminates the costly and time-consuming trial-and-error approaches traditionally used to set machine parameters and delivers substantial improvements on standard factory settings.

Machine tools optimized by Productive Machines can produce parts in half the original time and deliver significant surface quality improvements due to the mitigation of chatter created by instability in machining processes.

Users also report that cutting tools last up to 30 per cent longer on optimized machines.

Condition monitoring and predictive maintenance for all

We also help manufacturers use data from digital tap tests to support condition monitoring and predictive maintenance programmes.

These programmes rely on the analysis of data gathered from machines. Historically, highly skilled machine operators would perform tests, record findings relating to areas such as heat and machine vibration revealing signs of wear, fatigue and failure manually, and – based on their deep knowledge of those machines – identify if maintenance interventions were required to ensure optimal performance and prevent potentially catastrophic machine failures.

With Industry 4.0 and the advance of machine learning, large manufacturers have started to replace these labour-intensive approaches to assessing machines with data-driven technologies that automatically evaluate asset conditions, and do so more precisely and at a much greater scale.

This enables them to spot emerging problems and the signs of potential failures earlier, sometimes many months before even the most skilled machine operator could, and with greater consistency.

However, this form of automated condition monitoring and predictive maintenance is not available to everyone. Not all machines have sensors. Not all factories have the networking infrastructure to relay the data from sensors for analysis. And not all manufacturers like the idea of removing machine operators, those who know their machines best, from that loop.

In this context, the digital tap test is the manufacturers’ best friend. Machine operators can take this truly portable tool from machine to machine, and use it on machines of all ages to record exact vibration measurements that will show emerging problems that could affect those assets' productivity, quality and sustainability.

And it does this at any scale. Even the smallest machine shop with a digital tap hammer can now benefit from sophisticated data-driven analysis without requiring expensive new machinery, sensors or networking infrastructure. What’s more, a single laptop contains all the computing power needed to support this level of analysis.

We’ve just introduced software that analyses vibration data from digital tap tests and makes it meaningful for machine operators, so they can quickly adopt these kinds of condition monitoring and predictive maintenance capabilities.

Long live tap testing

The age-old practice of tap testing has not only endured but has evolved into an even more powerful tool in the era of smart manufacturing. From its humble origins to its current status as a critical component of quality control, material characterisation, structural health monitoring, and more, tap testing has proven its versatility and effectiveness.

Digital tap testing, enhanced by AI, has ushered in a new era of precision and efficiency in manufacturing. It empowers manufacturers to optimize machine tool performance, reduce waste, and enhance product quality.

Moreover, it democratises condition monitoring and predictive maintenance, enabling even small-scale operators to benefit from data-driven technologies without costly investments in sensors or infrastructure.

As the manufacturing landscape continues to embrace digital transformation, the digital tap hammer stands as a testament to the enduring importance of innovation in improving industrial processes and ensuring product quality.